New Optical Digital Comparator Ensures Critical Customer Dimensions are Consistently Met

The new measurement system allows API to quickly and efficiently measure all customer specified critical dimensions, track and document part variances and automatically create inspection reports.

As a leading global supplier of polarized materials and products, American Polarizers, Inc. has built its reputation on consistent, high quality products. To guarantee that large volumes of precision parts meet critical customer specifications, API performs rigorous inspections on all products before they are approved for shipment.

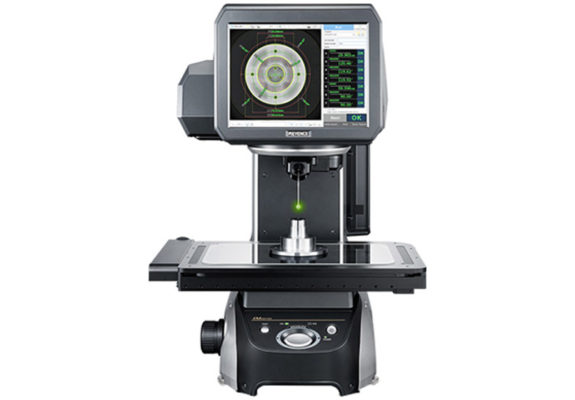

To further improve and streamline the inspection process API has invested in a digital optical comparator manufactured by Keyence, a leader in digital optical measurement systems. The new measurement system allows API to quickly and efficiently measure all customer specified critical dimensions, track and document part variances and automatically create inspection reports. Done in conjunction with their close tolerance XLS laser, the new measurement system allows API to consistently provide accurate and correct measurements ensuring adherence to tight tolerances on customer parts. As a by product of the inspection process, the system can generate statistical data when requested by their customers including providing CPK values to PPAP (Product Part Approval Process).

According to Nick Bentley, API’s CEO, “The acquisition of this machine is part of APIs strategic plan which includes the recent achievement of ISO 9001:2015. Our plan is to continuously improve our internal manufacturing processes to provide consistent products and our investment in this leading edge inspection equipment is proof of our commitment to that strategy.”

The Keyence Image Dimension Measurement System IM-7020 features include:

- Automatic recognition of part position and orientation

- Fast measurement – up to 99 dimensions can be measured in seconds

- Versatile programming for in-process and final inspections

- Accurate and repeatable measurements

- Measurement data is automatically saved and used to create inspection reports

In addition, bringing the process in house allows API to reduce inspection and recording time by eliminating the need to send parts out for evaluation. Overall, the new image measurement system enables API to improve product quality, statistical reporting and customer satisfaction.

For more information about American Polarizers optical films and custom cutting services, please contact API, 141 South Seventh St., Reading PA 19602. Tel: 610-373-5177. Fax: 610-373-2229. Email [email protected]. Web: www.apioptics.com