Nine Reasons to Choose API Optical Laminations for Your Next Project

If you’re looking for optical solutions, from practical to cutting-edge, you can trust API to provide industry-leading optical laminations.

At American Polarizers, we understand that the success of your product depends on the quality of your manufacturers. Here are nine reasons why we think our laminations are better:

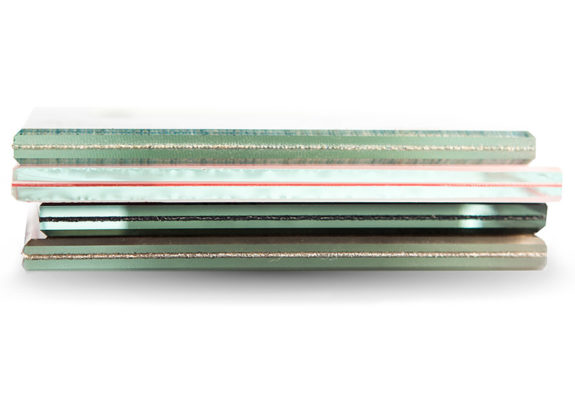

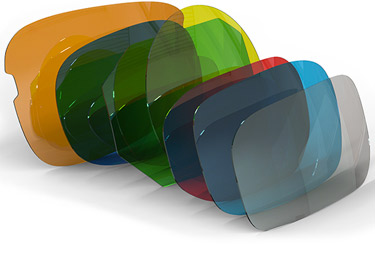

1 – Materials

API offers laminations with glass, acrylic, or film substrates in a broad range of colors and thicknesses. Depending on the materials and application, Optically Clear Adhesives (OCA) or UV Curing Adhesives are used for outstanding lamination to any substrate.

API offers laminations with glass, acrylic, or film substrates in a broad range of colors and thicknesses. Depending on the materials and application, Optically Clear Adhesives (OCA) or UV Curing Adhesives are used for outstanding lamination to any substrate.

2 – Clarity & Resolution

API’s acrylic and glass optical laminations offer low birefringence, high clarity and excellent resolution. For example, our glass laminations are used for filters in the demanding television and movie industry where picture quality is paramount.

3 – Cleanliness

Our manufacturing facility is designed to produce optical laminations with the utmost cleanliness to achieve the best yields and optical performance

4 – Environmental Stability

Offering superior heat and humidity resistance, our laminations can be designed for applications in harsh environments and with temperatures up to 70º C.

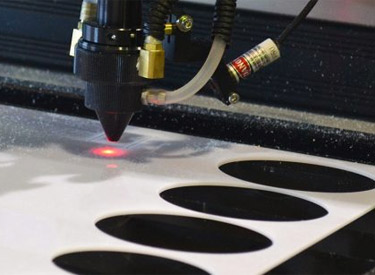

5 – Waterjet and Laser Jet Cutting

API can provide optical laminations in almost any shape or size to meet virtually any application. All laser and waterjet cutting is done in-house to facilitate cost control and reduce production cycle time. With six laser cutters and two waterjet cutting machines on-site, we are able to hold very tight tolerances when cutting intricate shapes with little damage to the edge of polarizing substrates. For example, we can produce glass parts as small as 11 mm diameter and our laser cutters have a beam diameter of only 25 microns to minimize heat damage from cutting.

API can provide optical laminations in almost any shape or size to meet virtually any application. All laser and waterjet cutting is done in-house to facilitate cost control and reduce production cycle time. With six laser cutters and two waterjet cutting machines on-site, we are able to hold very tight tolerances when cutting intricate shapes with little damage to the edge of polarizing substrates. For example, we can produce glass parts as small as 11 mm diameter and our laser cutters have a beam diameter of only 25 microns to minimize heat damage from cutting.

6 – Die Cutting and Machining

API also offers die cutting and machining services for a variety of non-metal materials, including plastics, gaskets, and tapes in large and small run quantities. If your part needs a ledge, bevel, or any special machining, count on API for a custom solution. Our in-house cutting capabilities combine high accuracy with the edge quality of die cutting for precise results every time.

7 – Custom Laminating Options

API offers a range of options to meet a wide range of application requirements including:

- Thick Film Coatings: hard coatings and anti-glare hard coatings

- Thin Film Coatings: anti-reflective, conductive and beam-splitter coatings

- EMI/RFI Shielding: transparent conductive coatings and optical conductive grids

8 – ISO 9001:2015 Quality Management System

API’s Quality Management System is backed up by our ISO 9001:2015 certification. This rigorous process involves implementing a Quality Management System to encompass all areas of business, including employee training, operating procedures, equipment maintenance, and technical documentation. All procedures are closely monitored, continuously improved, and updated.

API’s Quality Management System is backed up by our ISO 9001:2015 certification. This rigorous process involves implementing a Quality Management System to encompass all areas of business, including employee training, operating procedures, equipment maintenance, and technical documentation. All procedures are closely monitored, continuously improved, and updated.

9 – Member of SOSSEC for DOD Contracts

As part of the Member of Systems of Systems Consortium (SOSSEC) for DOD contracts, API works on solutions for government applications and has experience meeting stringent military and defense specifications and timelines.